Industrial hemp (Cannabis sativa L.) is grown for bast fibers and shiv/hurd (cellulose-rich wood core). In the hemp-lime system, shiv plays the main role: porous – lightweight – vapor permeable structure, creating the foundation for heat insulation and moisture cushioning; When used as bioaggregates with lime-based binders, the mixture achieves low thermal conductivity and high porosity. The recent review also emphasizes the role of handling and classifying shiv seeds, affecting the mechanical-thermal-moisture effects of the product [2][7].

Composition & Grade. Typical hemp-lime consists of shiv + natural hydraulic lime (NHL) or lime–cement + water. Thanks to the ~70–80% porosity, the dry thermal conductivity λ ≈ 0.05–0.12 W·m⁻¹·K (density dependent, humidity, binder type) – significantly lower than regular brick/concrete walls [2][3]. Vapor permeability – moisture buffering is good, contributing to the reduction of condensation and mold [2][6]. However, due to the low density of knitting tissue, hemp-lime is not used as a load-bearing component; it is a fill wall/envelope combined with an independent bearing frame (BTCT/steel/wood), in accordance with the spirit of Appendix BL [1][2].

Construction & finishing. Hemp-lime can be poured in place around the frame, lightly compacted in formwork, or prefabricated block/panel; The finish should be a vapor-permeable lime mortar/mineral paint, avoiding a vapor-tight film that causes "moisture lock". Experimental-simulation shows low thermal diffusivity and moisture stability of hemp-lime walls when the enclosure details are designed correctly [5][6].

Thanks to its low λ and capillary structure, the hemp-lime wall soothes day/night thermal fluctuations and has a high MBV, reducing the risk of condensation-mold in hot, humid climates [2][3][6]. Simulations of buildings in temperate/cool climates show that hemp-lime reduces the risk of mold and improves indoor environmental quality; The impact on operating energy depends on the enclosure configuration (thickness,finish) and HVAC system [5][6].

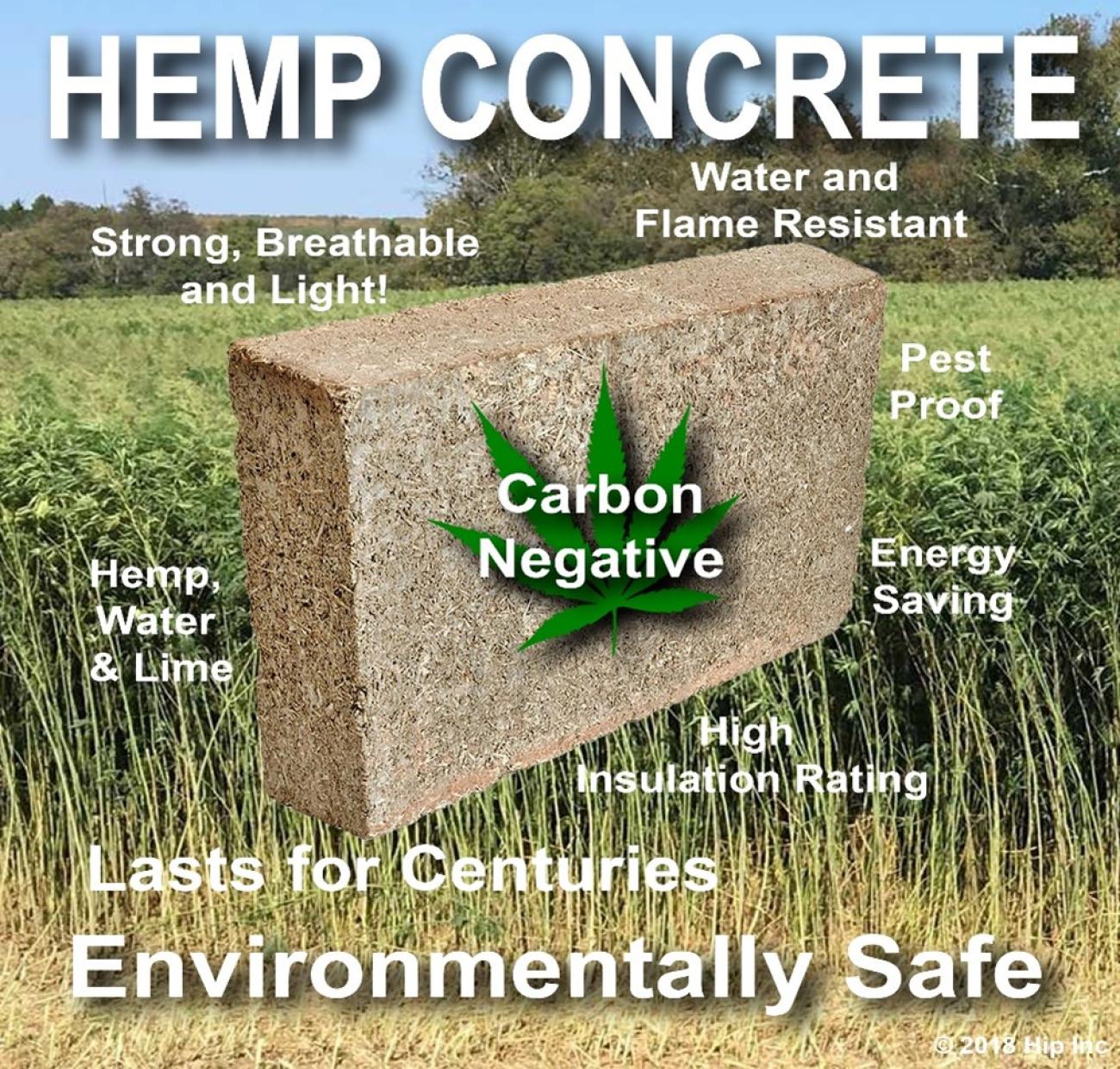

Hemp-lime is often seen as a carbon storage material thanks to the bio-CO₂ in hemp biomass and the carbonation of the binder during the use phase. However, "carbon negative" is conditional: LCA 2024 shows that the hemp:binder ratio, energy source, transport, and carbon biogenic calculation standard determines the carbon footprint; Some profiles reach neutral/negative, while a dominant binder configuration may lose its advantage [4].

IRC 2024 – Appendix BL officially includes hemp-lime in the housing code as a non-load-bearing filler wall, regulating the scope of application (scale, seismic, climate) and detailed requirements, paving the way for practical implementation at the scale of low-rise buildings [1].

Access: https://www.ushba.org/post/hemp-lime-appendix-published-in-2024-us-model-residential-housing-codes

High-performance enclosure/fill wall. The main application is to cover low-rise buildings and renovation works, aiming at heat insulation – humidity conditioning – sound insulation. Experiments show that λ dry ~0.05–0.12 W·m⁻¹· K in the typical sample; MBV at a "very good" level helps stabilize the humidity of indoor spaces [2][3][6]. Design recommendations: prioritize vapor-permeable finishes, treat rain splashes – moisture bridges – dew spots; Optimal Climate–Energy Target Binder Ratio/Density/Binder Ratio [2][6].

Prefabricated block/panel & upgrading. Hemp-lime can prefabricate blocks/panels to increase uniform quality, shorten construction time; Simulations/field testimonials have shown a significant reduction in the risk of mold and thermal stability when replacing brick/concrete walls with hemp-lime systems of equivalent thickness [5][6].

Note the limitations. Hemp-lime is not load-bearing; requires an independent bearing frame. Mechanical (compression, elastic) and long-lasting (wet–dry, salt, biological) depend on binder type – moisture – maintenance; Mechanical/long-lasting research emphasizes the need to detail the construction – protect the surface appropriately to ensure longevity [7].

Hemp-lime is a promising biobuilding shell candidate: good insulation, high humidity cushioning, improved indoor environmental quality, with the ability to reduce life-cycle emissions when the distribution – value chain – biogenic carbon is properly considered. Appendix BL (IRC 2024) creates a normative foundation for application in low-rise housing. For hot and humid markets (such as Vietnam), the feasible route is to pilot hemp-lime fill walls/panels on a small scale, assess heat-energy-LCA humidity on site, optimize the hemp:binder ratio and vapor permeable finish details before replicating [1][2][4][6].

[1] International Code Council (2024). APPENDIX BL—Hemp-Lime (Hempcrete) Construction, 2024 International Residential Code (IRC). Available at: codes.iccsafe.org. (ICC Digital Codes)

[2] Walker, R. and Pavía, S. (2014). Moisture transfer and thermal properties of hemp–lime concretes. Construction and Building Materials, 64, 270–276. https://doi.org/10.1016/j.conbuildmat.2014.04.081. (PDF access) (Ecomat - ecologische bouwmaterialen)

[3] Pochwała, S. (2020). The Heat Conductivity Properties of Hemp–Lime Composites.Materials(MDPI),13(4):1011. https://doi.org/10.3390/ma13041011. (MDPI)

[4] Shanbhag, S.S. et al. (2024). Examining the global warming potential of hempcrete in the United States: a cradle-to-gate LCA. Journal of Building Engineering, 95:109028. (indexed summary) (Directory of Open Access Journals)

[5] Shang, Y. et al. (2021). Hempcrete building performance in mild and cold climates: integrated analysis of carbon footprint, energy, and indoor thermal & moisture buffering. Building and Environment, 206:108370. https://doi.org/10.1016/j.buildenv.2021.108370. (Astrophysics Data System)

[6] Kaboré, A., Maref, W. and Ouellet-Plamondon, C.M. (2024). Hygrothermal Performance of the Hemp Concrete Building Envelope. Energies, 17(7):1740. https://doi.org/10.3390/en17071740. (MDPI)

[7] Walker, R., Pavía, S. and Mitchell, R. (2014). Mechanical properties and durability of hemp-lime concretes. Construction and Building Materials, 61, 340–348. https://doi.org/10.1016/j.conbuildmat.2014.02.065. (PDF access) (awarticles.s3.amazonaws.com)

[8] Tong, W. and Memari, A.M. (2025). State-of-the-Art Review on Hempcrete as a Sustainable Substitute for Traditional Construction Materials for Home Building. Buildings, 15(12):1988. https://doi.org/10.3390/buildings15121988. (MDPI)

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 11/10/2025

Amid rapid urbanization and global climate change, architecture is not only construction but also the art of harmonizing people, the environment, and technology. The Bahrain World Trade Center (BWTC)—the iconic twin towers in Manama, Bahrain—is a vivid testament to this fusion. Completed in 2008, BWTC is not only the tallest building in Bahrain (240 meters) but also the first building in the world to integrate wind turbines into its primary structure, supplying renewable energy to itself [1]. This article explores the BWTC’s structural system and design principles, examining how it overcomes the challenges of a desert environment to become a convincing sustainable model for future cities. Through an academic lens, we will see that BWTC is not merely a building but a declaration of architectural creativity.

The News 04/10/2025

As buildings move toward net zero architecture and glare free daylighting, traditional glass façades reveal limitations: high thermal conductivity (~0.9–1.0 W/m·K), susceptibility to glare, and shattering on impact. In this context, transparent wood (TW) is emerging as a multifunctional bio based material: it offers high light transmission yet strong diffusion (high haze) to prevent glare, lower thermal conductivity than glass, and tough, non shattering failure. Recent reviews in Energy & Buildings (2025) and Cellulose (2023) regard TW as a candidate for next generation windows and skylights in energy efficient buildings. [1]