When cement comes into contact with water, hydration occurs. This is an exothermic chemical reaction that produces binding products such as C-S-H (calcium silicate hydrate) and Ca(OH)₂. The heat generated gradually increases the temperature inside the concrete mass, especially in the core where heat dissipation is difficult.

Large-volume concrete dissipates heat very slowly. As a result, the heat from hydration is trapped, causing the core temperature to rise much higher than the surface. This temperature differential can easily lead to thermal stresses and cracking.

In addition to internally generated heat, concrete also absorbs heat from the environment, especially when construction takes place during the day or in hot weather. This further raises surface temperatures, increasing the temperature gradient between the surface and the core.

Excessive temperature leads to thermal cracking as the concrete cools.

Accelerated reaction rate makes the concrete set faster, increasing the risk of surface drying and plastic shrinkage cracks.

Long-term durability may be compromised, particularly in large mass concrete structures such as dams, foundations, and thick elements.

The Hoover Dam was not cast as a single continuous block. If it had been, the heat from hydration would not have dissipated, and the concrete core could have taken up to 125 years to fully cool—posing risks of cracking and structural failure. Instead, construction adopted a block-pour method, dividing the dam into rectangular blocks about 15 m x 15 m and 1.5 m high. This allowed faster heat dissipation and tighter control of the setting process. Once the concrete cooled, the joints between blocks were grouted to form a monolithic structure.

Each block was embedded with steel pipes 1 inch (25 mm) in diameter, totaling more than 580 miles in length. Initially, cool river water circulated through the pipes to lower the temperature; later, the system switched to chilled water supplied from a refrigeration plant.

The on-site refrigeration plant was one of the largest of its time, capable of producing about 1,000 tons of ice per day. Cold water from the plant was continuously pumped through the embedded pipes to extract heat, enabling the concrete to cool safely within months instead of decades.

The cooling process was carried out in two stages:

Circulating natural river water.

Circulating chilled water from the refrigeration plant.

The system was operated alternately across elevation zones to ensure optimal thermal conditions in each construction area and to prevent thermal stresses that cause cracking.

Block-pour method: prevents thermal cracking and accelerates cooling.

Integrated cooling system: enables real-time temperature regulation and control of thermal gradients (core–surface).

Dedicated refrigeration plant: ensures a stable and sufficient cooling supply, especially during hot seasons.

Post-cooling grouting: ensures strong bonding between blocks and restores monolithic integrity.

Two-stage, block-based cooling: became a benchmark for future large-scale concrete structures such as hydroelectric dams and massive foundations.

To mitigate thermal cracking in mass concrete, multiple strategies are applied simultaneously. First, the concrete mix is optimized by reducing cement content and substituting fly ash, slag, or pozzolans to lower hydration heat. Construction typically employs block pours, combined with cooling of water and aggregates, and embedded circulation pipes to extract heat internally. Externally, insulation blankets and continuous moist curing are used to prevent large surface-core temperature differences.

In parallel, temperature sensors are installed inside the mass to provide real-time monitoring, allowing timely interventions if thresholds are exceeded. Retarding admixtures and detailed thermal control plans are also vital tools, ensuring construction safety and long-term durability.

[1] “Why concrete gets so hot,” Construct Update, [Online]. Available: https://www.constructupdate.com/why-concrete-gets-so-hot/#gsc.tab=0. [Accessed: 27-Aug-2025].

[2] J. D. Rogers, “Hoover Dam: Operational Milestones, Lessons Learned and Strategic Import,” Hoover Dam 75th Anniversary History Symposium, Oct. 2010.

[3] “Guidelines for Temperature Control of Mass Concrete,” Auburn University Highway Research Center, Auburn, AL. [Online]. Available: https://eng.auburn.edu/files/centers/hrc/930-860r-temperature-control. [Accessed: 27-Aug-2025].

[4] EB547 – Mass Concrete Construction Guide, Portland Cement Association, 2024. [Online]. Available: https://www.cement.org/wp-content/uploads/2024/08/EB547. [Accessed: 27-Aug-2025].

[5] J. B. Alper, “Mass Concreting,” STRUCTURE Magazine. [Online]. Available: https://www.structuremag.org/article/mass-concreting/. [Accessed: 27-Aug-2025].

[6] R. Detwiler, “Thermal control plans for mass concrete,” Beton Consulting Engineers, 10-Sep-2020. [Online]. Available: https://www.betonconsultingeng.com/thermal-control-plans-for-mass-concrete-2/. [Accessed: 27-Aug-2025].

[7] “The Colorado River and Hoover Dam Facts and Figures,” U.S. Bureau of Reclamation. [Online]. Available: https://www.usbr.gov/lc/region/pao/faq.html. [Accessed: 27-Aug-2025].

The News 25/12/2025

Walking by Ba Son at night and seeing the sky like "turning on the screen"? It is highly likely that you have just met Saigon Marina International Financial Centre (Saigon Marina IFC) – a 55-storey tower at No. 2 Ton Duc Thang (District 1). The façade LED system makes the building look like a giant "LED Matrix": standing far away, you feel like the whole tower is broadcasting content, constantly changing scenes according to the script.

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

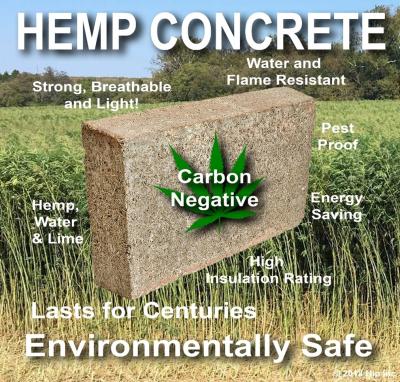

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.