A Smart Wall is an upgraded type of wall structure that goes beyond the traditional role of partitioning, load-bearing, soundproofing, or thermal insulation, becoming a system capable of monitoring and proactive response. Unlike conventional walls, smart walls are integrated with temperature, smoke, humidity, microwave sensors, or fire-sensitive materials within the structural layers. As a result, the wall not only provides protection but can also detect early risks such as fire, cracks, or mold and transmit warning data to the building management system.

Recent research has expanded this concept, turning the smart wall into part of the smart building ecosystem, where the wall can integrate fire protection modules (such as water mist spraying or fire-resistant materials), environmental sensors (CO₂, VOCs), and IoT connectivity to synchronize with security and energy management systems. Some microwave sensor technologies can even detect fires behind brick or concrete layers, enabling the wall not only to “resist fire” but also to “report fire.” In other words, the smart wall represents the convergence of building materials and technology, transforming a passive structure into an active “guardian,” enhancing safety, energy efficiency, and building lifespan.

Structurally, sensors can be installed directly into the finishing layer of the wall, such as recessed boxes, technical cavities, or embedded in panel modules. Additionally, sensors can be directly embedded into building materials, such as fiber optic sensors, conductive films, or heat-sensitive microcapsules.

Common sensor groups include:

Temperature sensors such as thermistors or RTDs, capable of detecting rapid temperature changes.

Smoke/particulate sensors, including photoelectric or ionization types, for detecting thin or dense smoke.

Toxic gas sensors, measuring CO, HCN, or volatile organic compounds (VOCs) using electrochemical, MOX, or PID technologies.

Pressure and impact sensors, designed to detect pressure changes or shocks during fire or explosion events.

Traditional fire-resistant walls are built from materials such as brick, concrete, gypsum, or specialized fireproof boards. Their role is passive—simply blocking flames, containing smoke, and insulating heat to meet safety standards, extending the fire resistance duration of the structure. However, these walls provide no warning or active assistance when an incident occurs.

In contrast, smart walls with integrated sensors retain the passive functions of fire-resistant materials but add proactive capabilities. Integrated temperature, smoke, toxic gas, and pressure sensors enable early fire detection before flames spread. Once abnormal signals are recorded, the wall can automatically trigger alarms, transmit information to a control center or mobile devices, and even activate other safety systems such as water mist suppression or smoke barrier closures. Thus, the wall evolves from a passive barrier into an active “guardian,” significantly reducing damage and enhancing safety for both people and property.

Low-cost gas sensors: Commercial gas sensors—though sometimes subject to cross-sensitivity—can still detect early gases generated during fires (VOC, CO, CO₂) at the incipient stage. Early fire detection is feasible, but the system must be calibrated to match the specific construction materials used.

Besides gas sensors, temperature sensors should be installed inside the structure to cross-verify readings, as gas sensor sensitivity degrades over time.

Combining both improves reliability, creating a smart early-warning system that relies on both combustion gases and temperature changes.

Crucially, calibration must match the building’s materials, as each emits characteristic gases during combustion.

Before testing or deployment, gas sensors (especially for CO, CO₂, and VOCs) must be verified and calibrated for accuracy. In real buildings, sensors should be installed for easy replacement or recalibration after prolonged use. VOC sensors, in particular, should be calibrated with a representative gas or organic compound.

[1] Wall-Smart Ltd., “Company posts,” LinkedIn. Available: https://www.linkedin.com/company/wall-smart-ltd-/posts/?feedView=all&viewAsMember=true. Accessed: Sept. 13, 2025.

[2] F. Alimenti, G. Tasselli, S. Bonafoni, D. Zito, and L. Roselli, “Inter-Wall Fire Detection by Low-Cost Microwave Radiometric Sensors,” in Proc. 38th European Microwave Conference, Amsterdam, The Netherlands, Oct. 2008, pp. 63–66.

[3] C. Zhong, T. Li, H. Liu, L. Zhang, and X. Wen, “Fire Reconstruction and Flame Retardant with Water Mist for Double-Roofed Ancient Buddhist Buildings,” Buildings, vol. 15, no. 7, p. 1109, Mar. 2025. doi: 10.3390/buildings15071109.

[4] A. Solórzano, J. Eichmann, L. Fernández, B. Ziems, J. M. Jiménez-Soto, S. Marco, and J. Fonollosa, “Early fire detection based on gas sensor arrays: Multivariate calibration and validation,” Sensors and Actuators B: Chemical, vol. 352, p. 130961, Oct. 2021. doi: 10.1016/j.snb.2021.130961.

The News 25/12/2025

Walking by Ba Son at night and seeing the sky like "turning on the screen"? It is highly likely that you have just met Saigon Marina International Financial Centre (Saigon Marina IFC) – a 55-storey tower at No. 2 Ton Duc Thang (District 1). The façade LED system makes the building look like a giant "LED Matrix": standing far away, you feel like the whole tower is broadcasting content, constantly changing scenes according to the script.

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

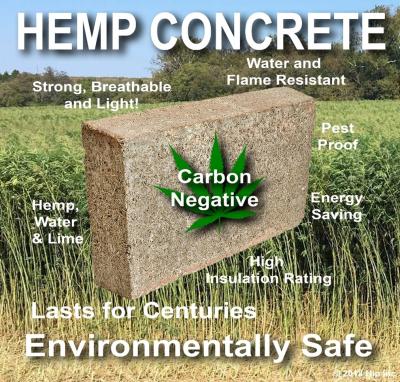

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.