Where Do Concrete Cracks Come From?

Concrete cracking is a phenomenon where the surface of concrete splits into lines or grooves. These cracks often lack uniformity in size, direction, or thickness. Over time, if not properly treated, these cracks may develop further and lead to unpredictable consequences.

This phenomenon is one of the main causes of reduced structural lifespan. Its impact may not be immediate, but it's difficult to determine the exact timeline. The consequence of concrete cracking is ultimately structural failure, causing not only property damage but also potentially threatening human lives. Therefore, treating concrete cracks is an extremely important issue that should be addressed as early as possible. However, before finding a solution, it is necessary to understand the reasons behind this phenomenon to propose the most reasonable approach.

What Causes Concrete Cracks?

Shrinkage Cracks: These cracks appear shortly after pouring concrete. They are narrow and resemble bird footprints. They occur because water evaporates too quickly from the surface, causing a deformation between the top and bottom of the slab. This often happens when concrete is poured during noon, in hot and dry weather.

Prevention: Avoid pouring concrete in intense heat. After pouring, properly finish the surface. Use wet sacks to cover and continuously moisten for 3 days.

Settlement Cracks: These occur when the foundation of a structure shifts. Settlement cracks are usually serious and may result from poor foundation treatment. Other causes include soil erosion or weak foundation soil. In shallow residential foundations surrounded by large trees, roots may cause cracking.

Structural Calculation Errors: These cracks are caused by design mistakes, where the load exceeds the concrete’s bearing capacity, leading to cracking or collapse. Although this issue is rare due to meticulous planning, it can happen when homeowners expand their houses without recalculating load capacity.

Material Issues: In modern construction, concrete is often sourced from mixing stations. From mixing to transportation and setting, concrete is affected by distance, method of transportation, mix ratio, heat of hydration, etc. These factors influence its quality. Additionally, variations in cement types, additives, cement strength, aggregate size, and flake content give concrete different material properties, contributing significantly to crack formation.

External Forces: These are forces acting on concrete from outside sources, such as earthquakes or human activities like drilling or geological surveys. Cracks from such forces are unpredictable and sudden, making them dangerous due to the lack of timely response. However, these cases are rare and not usually a major concern in practice0.

Time-Related Cracks (Corrosion): When reinforced concrete is exposed to moisture and oxygen, corrosion may occur. This happens through small cracks that allow water to reach the steel reinforcement, causing it to rust and expand, pushing the concrete out and creating larger cracks. Regular inspection and early treatment of small cracks can prevent serious damage.

What is the MICP Method?

Crack healing in concrete using MICP (Microbially Induced Calcium Carbonate Precipitation) is an advanced biotechnology that uses bacteria to precipitate calcium carbonate (CaCO₃), sealing fine cracks in concrete. This is an environmentally friendly, self-healing method that is gaining attention in sustainable construction.

How Does the Crack-Healing Process Work?

Stage 1: Preparation

Select bacteria (Sporosarcina pasteurii)

Prepare a nutrient medium for the bacteria

Use aggregate capable of alkali-silica reaction

Stage 2: Bacterial Culture in Solution

Bacteria are cultured for strong growth

They produce urease – the enzyme that breaks urea into NH₄⁺ and CO₃²⁻

Stage 3: Biological Reaction

Bacteria hydrolyze urea

Generate NH₄⁺ and increase pH

Create CO₃²⁻ ions

Stage 4: CaCO₃ Precipitation

CaCO₃ precipitates on aggregate surfaces, forming a protective layer

Bibliography

[1] C. T. T. S. - X. T. P. KHÁNH, "Nguyên nhân của nứt bê tông," Chống Thấm Phú Khánh, [Online]. Available: https://chongthamphukhanh.com/tin-tuc/nguyen-nhan-cua-nut-be-tong-43.html

[2] C. T. T. T. K. V. X. D. SBS, "Nguyên nhân và biện pháp xử lý vết nứt sàn bê tông," SBS House, [Online]. Available: https://sbshouse.vn/nguyen-nhan-va-bien-phap-xu-ly-vet-nut-san-be-tong/

[3] G. Magtech, "Phân tích nguyên nhân gây ra vết nứt trong kết cấu bê tông," Precast Concrete Magnet, [Online]. Available: https://vn.precastconcretemagnet.com/news/analysis-on-the-causes-of-cracks-in-concrete

The News 25/12/2025

Walking by Ba Son at night and seeing the sky like "turning on the screen"? It is highly likely that you have just met Saigon Marina International Financial Centre (Saigon Marina IFC) – a 55-storey tower at No. 2 Ton Duc Thang (District 1). The façade LED system makes the building look like a giant "LED Matrix": standing far away, you feel like the whole tower is broadcasting content, constantly changing scenes according to the script.

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

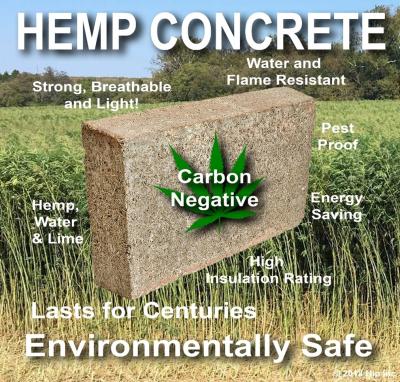

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.