3D concrete tiles are tiles cast from concrete, featuring raised three-dimensional shapes that create a strong visual impression. They are commonly made from glass fiber reinforced concrete (GRC), which enhances strength and reduces weight. These tiles offer water and heat resistance and are less affected by weather conditions. They suit various design styles from modern to classical, and can be used for paving paths, decorating walls, rooms, and staircases, offering both safety and visual appeal.

Geometric 3D Concrete Tiles: These come in a wide variety of patterns and unique designs, from triangles and hexagons to abstract forms. They are often used to decorate walls and create eye-catching focal points in living spaces.

Organic / Nature-Inspired Tiles: These tiles mimic natural forms such as waves, stone veins, seashells, leaves, tree bark, or petals—creating a soft, close-to-nature, artistic effect.

Interior 3D Tiles: Used for wall cladding, made from concrete or geopolymer, featuring 3D patterns that add visual depth and dynamic light-shadow interplay. They enhance the aesthetic and spatial quality of interiors.

Exterior 3D Tiles: Designed for outdoor durability, made from high-strength concrete or geopolymer. These tiles offer enhanced resistance to UV rays, moisture, and cracking—ideal for facades, fences, gardens, and public spaces.

Standard Concrete Tiles: Made from conventional concrete (cement, sand, fine aggregates, water, and additives), with 3D patterned surfaces. This is the most affordable and widely used type, suitable for large-scale production and simple applications.

GRC Tiles (Glassfiber Reinforced Concrete): Produced with composite material made of cement, fine sand, water, additives, and alkali-resistant glass fibers. These tiles are lightweight, durable, and suitable for detailed forms—ideal for interiors, facades, sunshades, and columns.

UHPC Tiles (Ultra-High Performance Concrete): Made from UHPC, a new-generation material with superior strength, formability, and longevity. These premium tiles are ultra-thin, high-strength, weather-resistant, and perfect for modern architecture, high-rise facades, and signature projects.

Material Preparation

Dry Mixing: All dry materials are added to a Hobart mixer and mixed at low speed for 3 minutes.

First Water Addition: 85% of total water is added and mixed at medium speed for 10 minutes.

Final Water Addition: The remaining 15% water is added and mixed for 5 more minutes to fully dissolve the solid activator.

Note: Extended mixing time ensures complete dissolution of Na₂SiO₃ and even distribution of the geopolymer activator.

3D Printing of Geopolymer Concrete Mixture

Printer Type: 3-axis gantry system (print dimensions: 1800 × 1600 × 1800 mm)

Extruder: Spiral-type nozzle, 30 mm outlet diameter

Printing Speed: 10 mm/s

Layer Dimensions: 30 mm wide × 20 mm high × 300 mm long

Surface Protection: Plastic wrap is applied immediately after printing to prevent water loss

Thermal Curing

After 24 hours of printing, samples are cured at 60°C for 24 hours.

Samples are then stored in a sealed room at ambient temperature until testing.

Purpose: Accelerates geopolymerization, especially important for brick waste with low amorphous content.

[1] C. T. T., J. V. Nam, "99 mẫu gạch ốp tường phòng khách 3D mới nhất, đẹp mắt 2025", Jorakay.vn, 15-May-2025. [Online]. Available: https://www.jorakay.vn/news/chia-se-huu-ich/gach-op-tuong-phong-khach-3d-la-gi. [Accessed: 30-Jun-2025].

[2] C. T. T., M. T. V., K. T. H. Minh, "Gạch 3D bê tông nghệ thuật", Bê Tông Hoàng Minh. [Online]. Available: https://betonghoangminh.vn/danh-muc-san-pham/gach-3d-be-tong-nghe-thuat. [Accessed: 30-Jun-2025].

[3] S. R. J. S. K. Pasupathy, "3D concrete printing of eco-friendly geopolymer containing brick waste," Cem. Concr. Compos., vol. 138, 104943, 2023. [Online]. Available: https://www.sciencedirect.com/science/article/pii/S0958946523000173. [Accessed: 30-Jun-2025].

The News 25/12/2025

Walking by Ba Son at night and seeing the sky like "turning on the screen"? It is highly likely that you have just met Saigon Marina International Financial Centre (Saigon Marina IFC) – a 55-storey tower at No. 2 Ton Duc Thang (District 1). The façade LED system makes the building look like a giant "LED Matrix": standing far away, you feel like the whole tower is broadcasting content, constantly changing scenes according to the script.

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

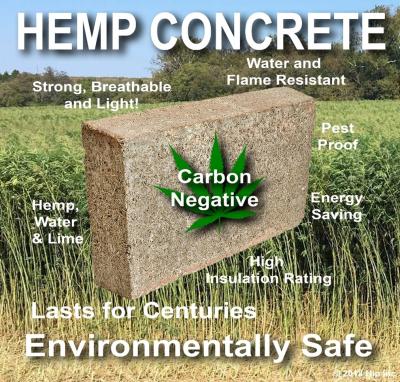

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.