What is the Mortise and Tenon Structure?

The mortise and tenon structure is a woodworking joint where one component (the tenon) is inserted into a corresponding cavity (the mortise) to form a stable connection without nails or glue. Historically used in temples, furniture, and wooden equipment, this technique requires high precision and craftsmanship. With the advancement of digital fabrication and CNC machinery, mortise and tenon structures are now more accessible and adaptable for contemporary product design.

Types of Mortise and Tenon Joints

|

|

These adaptable joint styles give designers the freedom to create functional and aesthetically distinctive products, suitable for a wide range of applications in the cultural and creative industries.

Advantages of Using Mortise and Tenon Structures in Product Design

The mortise and tenon system promotes modularity. Each part functions independently but can be interchanged or replaced easily. This allows for:

|

|

This modular flexibility aligns well with today’s sustainable design goals and the rising demand for personalized consumer products.

Mortise and tenon joints allow for imaginative structural modeling. The variety of joint types supports:

|

|

Even with simplified processing using modern tools, the essence of traditional mortise and tenon craftsmanship remains intact, allowing designers to meet both functional needs and aesthetic preferences.

Traditionally using wood, mortise and tenon structures naturally align with eco-conscious design. Their advantages include:

As sustainable design becomes more critical, mortise and tenon structures offer a tangible way to integrate green principles into modern products.

Cultural and Creative Product Innovation: Real-World Applications

In the globalized cultural and creative industry, product design is no longer just about function—it’s about storytelling, identity, and heritage. The mortise and tenon structure, when integrated with modern creativity, adds cultural depth and engineering strength to product design.

Case Study 1: Dovetail Business Card Case

One product cleverly integrates a sycee-shaped dovetail joint to form a modern business card case. The weight of the tenon replaces traditional clamps, ensuring a secure fit while providing a minimalist, heritage-inspired aesthetic. The ease of assembly and replacement of parts increases product longevity and adaptability for various user needs.

Case Study 2: NUDE Coatrack

Award-winning product NUDE, inspired by the traditional Luban lock, demonstrates how the mortise and tenon concept can be translated into contemporary furniture. The product uses angled interlocks for stability, eliminating the need for external fasteners. Its six-part design shares stress loads evenly, making it durable, easy to disassemble, and environmentally friendly.

Design Considerations for Cultural Products Using Mortise and Tenon

Conclusion: Beyond Aesthetic—Toward Functional Culture

The mortise and tenon structure is not merely a traditional craft—it is a design philosophy rooted in sustainability, modularity, and cultural identity. When applied thoughtfully to cultural and creative products, it brings together the past and present in ways that are both functional and meaningful. For designers aiming to balance modern innovation with historical depth, the mortise and tenon joint is not just a tool—it is a bridge between cultures, timelines, and design ideologies.

As the world grows more interested in sustainable and culturally grounded design, continued exploration of mortise and tenon structures will be essential. This isn’t just about reviving a technique—it’s about reshaping how we think, create, and connect through products.

Source: IOP Conference Series: Materials Science and Engineering

The News 25/12/2025

Walking by Ba Son at night and seeing the sky like "turning on the screen"? It is highly likely that you have just met Saigon Marina International Financial Centre (Saigon Marina IFC) – a 55-storey tower at No. 2 Ton Duc Thang (District 1). The façade LED system makes the building look like a giant "LED Matrix": standing far away, you feel like the whole tower is broadcasting content, constantly changing scenes according to the script.

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

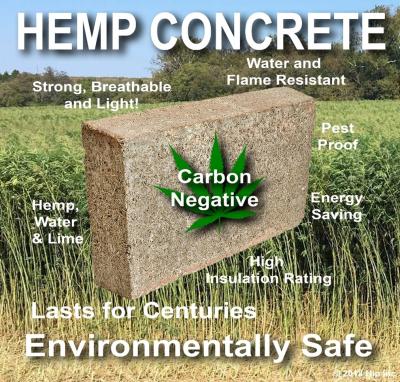

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.