1. Environmental Principles

Establishing an environmental policy is crucial for guiding corporate environmental actions. Many North American stainless steel producers, alongside the Specialty Steel Industry of North America (SSINA), adhere to principles promoting compliance with environmental laws while supporting economic growth. Key guiding principles include:

2. Environmental Management Systems

Effective environmental management requires commitment from top management. SSINA member companies often have dedicated Environmental Affairs Departments that ensure regulatory compliance and address environmental issues.

3. Materials, Energy, and Water Usage

The environmental impact of stainless steel production involves:

4. Pollution Prevention

Air Emissions: Emissions from electric furnaces and AOD vessels are captured through ductwork and directed to high-efficiency fabric filters for metal recovery. Acid pickling emissions are routed to fume scrubbers, with many operations employing chemical scrubbers for enhanced removal.

Water Treatment: All plant water is treated before discharge. Wastewater is collected from various sources, clarified, and filtered for reuse. Acid metering and recovery equipment in the pickling process minimize waste and recycle used acid.

5. Waste Minimization

Minimizing waste is a key objective in the stainless steel industry. Scrap products, including discarded pieces and packaging materials, are collected and recycled into the electric furnace to reduce solid waste generation.

6. Recycling

Stainless steel products are 100% recyclable, maintaining their value even after long use. Items such as kitchen sinks, automotive parts, and building materials can be fully recycled. The long lifespan of stainless steel minimizes the need for new resources, and scrap is collected globally for remelting, producing stainless steel of the same quality as the original.

7. Environmental Compliance Evaluations

Evaluations assess whether practices meet legal and internal environmental standards, with SSINA member companies adhering to these practices.

8. Participation in Cooperative Environmental Councils and Partnerships

The stainless steel industry actively engages with various governmental and environmental councils, including participation in the Common Sense Initiative, which aims to streamline regulations. Member companies have also contributed to the federal 33/50 Program, reducing targeted chemical releases by 50% based on 1994 data. Local involvement includes environmental initiatives like River Sweep and various recovery projects.

9. Communication of Environmental Activity

Effective communication reflects an organization's commitment to the environment. SSINA member companies utilize employee newsletters, training, websites, press releases, and public presentations to disseminate environmental information.

10. Environmental Releases and Sustainable Relationships with the Natural Environment

Environmental performance is often measured by hazardous waste released. The specialty steel industry recycles 100% of electric furnace dust for metal recovery and operates acid recovery units to minimize waste pickle liquor. All waste pickle liquor is either recycled or treated to render it non-hazardous before disposal.

Source: Specialty Steel Industry of North America (SSINA).

The News 25/12/2025

Walking by Ba Son at night and seeing the sky like "turning on the screen"? It is highly likely that you have just met Saigon Marina International Financial Centre (Saigon Marina IFC) – a 55-storey tower at No. 2 Ton Duc Thang (District 1). The façade LED system makes the building look like a giant "LED Matrix": standing far away, you feel like the whole tower is broadcasting content, constantly changing scenes according to the script.

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

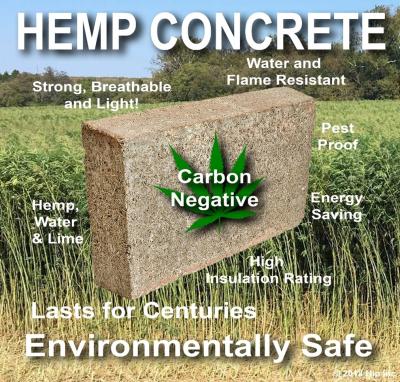

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.