1. Origin and Emergence of Hue Enamelware

According to historical records, in the winter of the Đinh Hợi year (1827), Emperor Minh Mang (1820 – 1841) established the Pháp Lam Tượng Cục—a special agency dedicated to enamelware production. This agency, consisting of 15 artisans, was led by Vu Van Mai, a renowned painter from the Nội Tạo workshop (a department responsible for painting and decoration in the royal court).

Besides the enamelware workshop in Hue, the Nguyen Dynasty also established additional workshops in Ai Tu (Quang Tri) and Dong Hoi (Quang Binh) to produce enamelware for decorating royal palaces, mausoleums, and ritual objects. This marks 1827 as the official birth year of Hue enamelware in Vietnam.

2. Influence and Techniques of Hue Enamelware

Researchers suggest that the enamelware techniques of the Nguyen Dynasty were directly influenced by Guangdong, China. However, China was not the only country producing enamelware; nations such as England, France, the Netherlands, Germany, Italy, and Japan also developed enamel arts under different names.

According to the Hue Royal Antiquities Museum, Hue enamelware is classified into four types based on manufacturing and glazing techniques:

Guangdong was a famous enamelware center in ancient China, and its painted enamelware was introduced to Vietnam via Chinese merchant ships.

3. The Meaning Behind the Name "Pháp Lam"

The name Pháp lam in Vietnam has been a topic of much discussion among scholars. Around the world, enamelware is known by different names:

Many theories suggest that the Nguyen court changed the term from pháp lang to pháp lam to avoid overlapping with names in the royal family. Some believe that the Hue dialect does not differentiate between lang and lam, leading to the change. Another theory suggests that it was to avoid using the name of Lord Nguyen Phuc Lan or Empress Tong Thi Lan (wife of Emperor Gia Long).

Another explanation is that "pháp" means rules or laws, while "lam" refers to the blue enamel color, implying that pháp lam refers to enamel-coated metal objects crafted under strict artistic principles.

4. The Rise and Decline of Hue Enamelware

The craft of Hue enamelware lasted only about 60 years (1827 – 1888), whereas Chinese falang craftsmanship thrived for over 700 years. As a result, in terms of shaping, glazing, color mixing, decoration, and firing techniques, Hue enamelware was inferior to its Chinese counterpart.

Hue enamelware was not widely used among commoners but was primarily reserved for the Nguyen royal court. After 1945, the number of remaining Hue enamel artifacts became scarce, and the craftsmanship was lost. Despite various restoration efforts, traditional Hue enamelware has yet to be fully revived.

5. Unique Characteristics of Hue Enamelware

Hue enamelware flourished under the reigns of Minh Mang, Thieu Tri, and Tu Duc, when the Nguyen Dynasty was at its peak. Hue artisans developed distinct color-coordination techniques that helped enamelware withstand the harsh climate of Central Vietnam.

Hue enamelware was used to decorate the exteriors of imperial buildings and temples, including:

Common decorative motifs included dragons, phoenixes, flowers, and poetry, with traditional colors such as purple, red, blue, and yellow. Besides royal architecture, Hue enamelware was also used for household items, ritual objects, and souvenirs, such as bowls, plates, incense burners, and vases.

Artifacts preserved at the Hue Royal Antiquities Museum indicate that Nguyen Dynasty enamelware had a unique identity, distinct from Ming and Qing Dynasty enamelware of China. This distinction highlights the exceptional skills of Vietnamese artisans and affirms Hue enamelware's historical and artistic value.

The News 25/12/2025

Walking by Ba Son at night and seeing the sky like "turning on the screen"? It is highly likely that you have just met Saigon Marina International Financial Centre (Saigon Marina IFC) – a 55-storey tower at No. 2 Ton Duc Thang (District 1). The façade LED system makes the building look like a giant "LED Matrix": standing far away, you feel like the whole tower is broadcasting content, constantly changing scenes according to the script.

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

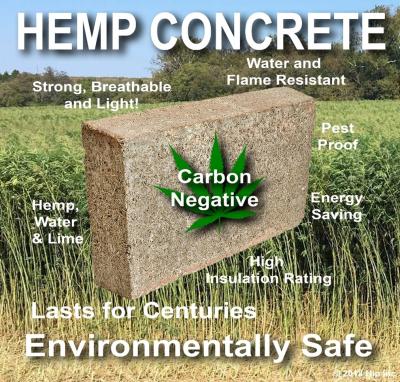

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.