COR-TEN: The origins of weathering steel

Weathering steels were first developed by US Steel Corporation back in the 1930s. They were looking for a steel alloy for their ore carrying hopper carts they would use to transfer the iron ore and coal to the furnace. They needed a stronger, more durable steel alloy that had exceptional hardness and did not need to be painted. It was only later they realized this alloy had interesting corrosion resistant traits that could be marketed in other industries, so it trademarked the name COR-TEN® for this corrosion-resistant steel alloy. COR stands for corrosion resistance and TEN stands for tensile strength. (Today, while the terms Corten and COR-TEN are used interchangeably, COR-TEN® is a trademarked product of US Steel.)

The steel was not introduced as an architectural metal, however, until the 1950s. In 1964, the John Deere Headquarters, in Moline, Illinois, opened and was one of the first major architectural structures to be clad in weathering steel. Eero Saarinen designed the John Deere complex but, unfortunately, he died before seeing it completed.

William Hewitt, then president of the John Deere company, said:

“The seven buildings should be thoroughly modern in concept but should not give the effect of being especially sophisticated or glossy. Instead, they should be more ‘down to earth’ and rugged.

|

Richard Serra Sculpture |

|

Saarinen chose this special weathering steel, Corten, to age and provide the earth tones and the “down to earth” feel his client desired. He knew the metal would age gracefully and create a deep, natural tone as the thickened oxide formed. The deep rich surface oxide exhibits a natural brownish-red tone that is both durable and stable.

Many artists have also incorporated weathering steel into their work, the most well-known being Richard Serra. Serra has used weathering steel plates on numerous massive sculptures found around the world.

The great minimalist artist Donald Judd also used weathering steel in his works. Judd would often preweather large plates and then allow them to continue to oxidize outdoors in Marfa, Texas. He also created smaller weathering steel wall units where he worked the surface oxide to create a fine velvet-like appearance.

Easy to work with, weldable, and now with appealing surface finishing, weathering steel is giving new value and inspiration to the designer and artist.

What is weathering steel?

In the context of art and architecture, steels are rarely used uncoated because of their tendency to absorb moisture and develop the porous and friable oxide commonly called rust. Coatings can consist of a sacrificial zinc, as in the galvanizing process where the steel is electroplated

or immersed into a molten bath of zinc. Other metal coatings in common use are the aluminum–zinc coatings and Galfan™, a combination of zinc and rare earth metals. These are all considered sacrificial coatings of other metals that involve the protection of the base steel by offering up their electrons as well as acting as barrier coatings.

In addition to the preweathering rust effects, there are also treatments that induce a blue or black protective coating on the steel, such as Oscura blackened steel. These involve the integration of metal salts onto the surface of the steel. There is some diffusion of the iron into these coatings to create the dark, sulfide, phosphate or selenide salt. Not as protective as the sacrificial coating of zinc in the galvanized process, these coatings are often applied to smaller features, pieces and areas.

Weathering steel, with its copper-bearing properties, forms its own distinctive oxide barrier over the surface. This barrier grows outward and inward from the surface. Unlike common rust, the oxide formed on weathering steel is a thick, impervious ferro-oxyhydroxide that will afford the base metal extensive resistance to corrosion. Below are some of the most common coatings applied when necessary for internal and external design, in art and architecture.

Surface Coatings on Steel Used in Art and Architecture

High-strength, low-alloy weathering steels are designed to develop a special thick iron oxide capable of slowing down the effects of atmospheric corrosion much like the green patina that develops on copper surfaces exposed to the atmosphere. This oxide grows on exposure to moisture and air.

As with all uncoated steels, the oxide develops when the surface is exposed to moisture and oxygen. For the weathering steels, however, the difference lies in the nature of the oxide that develops over time.

The oxide that gives weathering steel its protective ability is ferric oxyhydroxide, FeO(OH) an oxygenated version of ferric oxide — essentially, a mixture of oxides and hydroxide. This attractive, orange to rich purple brown oxide acts as a protective barrier to the base metal. When correctly formed, this tough layer of oxide develops into a surface that resists atmospheric degradation in outdoor environments. Once the oxide develops correctly, further changes are very slow in most environmental exposures.

Source: Zahner

The News 25/12/2025

Walking by Ba Son at night and seeing the sky like "turning on the screen"? It is highly likely that you have just met Saigon Marina International Financial Centre (Saigon Marina IFC) – a 55-storey tower at No. 2 Ton Duc Thang (District 1). The façade LED system makes the building look like a giant "LED Matrix": standing far away, you feel like the whole tower is broadcasting content, constantly changing scenes according to the script.

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

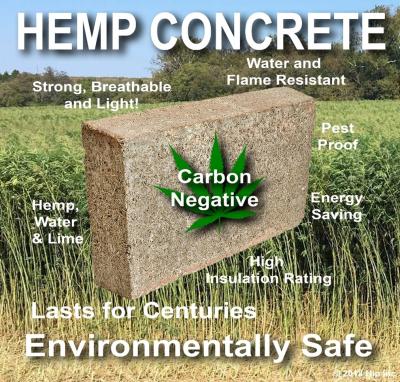

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.