GENTA VN.,JSC

Architecture Lobby and Corridor , Living room , Office, Working place

Classification Residential Buildings , Commercial Buildings , Industrial Buildings

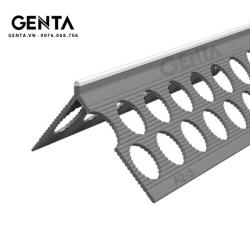

Wall plastering strips are also known as plastering strips or mortar strips. The most common material for these strips is uPVC plastic, which is rust-resistant, temperature-stable, has high mechanical strength, and good impact resistance.

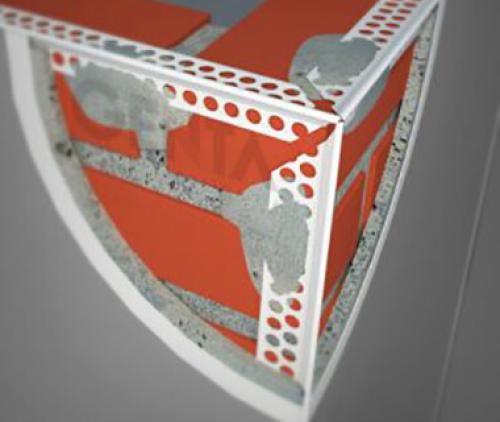

This product is used to "position" the plastering surface, creating corners and edges for the plastering. Before plastering, the contractor will insert the trim into the wall to create a "guide" or "marker" . Then, they simply move the ruler along the edge of the trim – a simple operation that is less dependent on the worker's skill.

Nowadays, contractors and architects often use plastic wall trim for projects such as houses, high-rise apartments, schools, hospitals, and public buildings.

In the past, the process of plastering walls was usually done manually and heavily dependent on the skill of the worker. Therefore, the quality of the plastering was often not high and inconsistent (some areas looked good, others looked bad).

Currently, wall plastering strips are used as a replacement for manual methods, thanks to the following advantages:

Using plaster strips offers several advantages, such as:

Using all types of products will yield the best results for your plastering project. However, depending on your purpose and budget (even if it's not significant), you can use only a few specific types of plastering strips.

This is the most common type of corner trim used for plastering walls. The product helps create sharp, clean edges and prevents chipping of columns and wall edges.

Plastic corner trim strips for plastering walls are usually made from uPVC material, which has the advantages of being durable, aesthetically pleasing, easy to install, and easy to maintain.

Typically, the recessed wall joint is the most prone to defects. Poor workmanship can create uneven, winding lines that are susceptible to cracking. The best solution is to use recessed wall joint trim strips (wall joint seals).

This type of decorative wall trim offers a "breakthrough" in finishing quality. Using this trim creates a sharp, recessed line that is vastly superior to manual application.

Instead of using manually constructed raised water channels, people use water-stopping strips to create water stopping points at locations such as balconies, loggias, lintels, etc., preventing water from flowing back into the house.

The water-stopping strip will create a secure, recessed seam that won't break or fall off. In particular, the strip is made from high-quality plastic, resistant to weather changes, and suitable for exterior applications.

Wall plastering strips are used to create recessed gaps or joints. They serve to separate the plaster from other materials such as wood, brick, or stone. This results in a refined and polished finished wall, preventing plaster from smearing onto the wood, brick, or stone.

Using plastic wall trim strips to separate gaps helps to simplify the use of traditional (classic) raised moldings. This contributes to creating a modern (minimalist) architectural style for the building.

Plastering guide strips create straight and quick plastering markers on the wall. After attaching the strips to the wall surface, you simply apply plaster according to the pre-aligned markers.

Compared to using stone plastering markers, attaching plastic plastering strips will result in a more perfectly smooth surface. In particular, using these markers is faster and eliminates the need to remove them after plastering is complete.

This type of plaster trim is used to finish the plaster at the point where it intersects with other materials. It is commonly used to create recessed baseboards or to tile flush with the plaster.

Using mortar leveling strips will result in straight, clean plaster lines without mortar smudging, overcoming many of the drawbacks of conventional recessed baseboard tiling.

Plastic corner plastering strips are used to create a flat plastering guide for recessed corners. In reality, plastering recessed corners is a difficult, time-consuming process that requires skilled workers. Using these strips to create a corner guide makes the job easier and saves much more time compared to doing it by hand.

This product is commonly used in areas such as: recessed corners where walls meet, recessed corners where walls meet ceilings, and recessed corners (inner corners) of architectural details finished with plaster.

Besides plastic plastering strips, there are many other types of plastering strips made from metal. However, because Vietnam's weather changes year-round, people prefer to use plastic plastering strips to avoid shrinkage that could affect the quality of the wall.

The price of uPVC plastering trim strips ranges from 8,000 to 15,000 VND per meter, depending on the design and quality of the plastic. The strips are packaged in boxes of 50, each strip measuring 2.2 to 2.5 meters in length. The selling price is from 1,000,000 to 1,500,000 VND per box , which is cheaper than buying them individually.

In reality, that's not the general price for all plastic wall trim products. Some cheaper types are made of lower-quality plastic. The trim strips are thin and easily warp during installation. You should consider this when choosing to buy these types of trim.

To make using plaster moldings easier for your project, you should include the molding details from the very first stages of the project. There are two ways to do this:

The method for installing plastic wall trim is quite simple. A worker only needs to watch a video or follow the instructions once to be able to do it.

The most efficient way to arrange a team of workers is as follows:

This is the optimal method that yields the highest wall plastering speed.

Mistakes in installing plastering strips can seriously affect the quality of the construction. To ensure the effective use of plastering strips, you need to pay attention to the following: